THE HEATSINK GUIDE: Peltier Guide, Part 1

History and introduction

In 1821, J. T. Seebeck (1770-1831) discovered that dissimilar metals that are connected at two different locations (junctions) will develop a micro-voltage if the two junctions are held at different temperatures.

This effect is known as the "Seebeck effect"; it is the basis for thermocouple thermometers.

In 1834, a scientist called Peltier discovered the inverse of the Seebeck effect, now known as the "Peltier effect":

He found that if you take a thermocouple and apply a voltage, this causes a temperature difference between the junctions.

This results in a small heat pump, later referred to as also known as a thermo-electric cooler (TEC).

Practical TECs use several thermocouples in series, which allows a substantial amount of heat transfer. A combination

of the semiconductors Bismuth and Telluride is most commonly used for the thermocouples; the semiconductors

are heavily doped, which

means that additional impurities are added to either create an excess (N-type semiconductor), or a lack (P-type semiconductor)

of free electrons. The thermocouples in TECs are made of of N-type and P-type semiconductor pieces bonded together.

Since peltier elements are active heat pumps, they can be used to cool components below ambient temperature - which

is not possible using conventional cooling, or even heat pipes.

What is a peltier cooler?

A peltier cooler is a cooler that uses a peltier element (TEC). Peltier coolers consist of the peltier element itself,

and a powerful heatsink/fan combination to cool the TEC.

Peltier basics

The typical maximum temperature difference between the hot side and the cold side of a TEC, referred to as delta Tmax, is around 70°C.

Does this mean that simply adding a peltier element between heatsink and heat source will cause the temperature

of the cooled device to drop by 70°C? No, that would be too good to be true. Two important factors must be considered:

-

The specified maximum value of delta T only occurs when the peltier element does not transport any heat - a situation

that does not occur in real-life cooling solutions. The actual delta T is a linear function of the power transferred

through the thermal element, with negative slope. An example of such a function, for one particular TEC, is

illustrated in the following graph, which is a stripped-down

version of the graph found in part 2 of the Peltier Guide.

Looking at the graph, you can see that, for example, if the peltier element will have a delta T of 55°C if it has

to move 10W of power (in the form of heat).

You will also see that at one point - at 40 Watts in the case of this example - delta T becomes zero. This occurs when

the TEC has reached its maximum thermal transfer capability (Qmax). So, our example peltier element cannot transport more

than 40W. I admit that this graph is a bit oversimplified; in following parts of the Peltier Guide we will get into more detail.

- Imagine that you are cooling a CPU with a power usage of 35W, using a conventional heatsink.

Will the temperature drop if you add our example peltier element between CPU and heatsink?

No. For a simple reason: In addition to transporting heat, peltier elements also

emit considerable amounts of heat (and thus use considerable amounts of electricity). So,

the heatsink will have to dissipate substantially more heat than before, and will get much hotter.

We will get into more detail about this issue in Part 3 of the Peltier Guide, where we analyze

under which circumstances a peltier element is useful, and under which conditions you are better off

with just a conventional heatsink.

Peltier elements have very low efficiency. They will consume more power than they transport!

Actual peltier elements may consume twice as much energy (in the form of electricity) as they transport

(in the form of heat). So, if you are using a peltier element, the heatsink it is used with must be

much more powerful than a heatsink used for cooling a heat source without peltier element.

Do not confuse the maximum amount of power a peltier element can transport with the

maximum amount of power usage of the peltier element. Some retailers sell "80W peltier element",

without stating what this value actually means. This is misleading - what you want is a high transport capability,

but a low power consumption.

To help you decide what kind of peltier element you need for an overclocked CPU, you can find instructions

for estimating power usage of overclocked CPUs here on The Heatsink Guide.

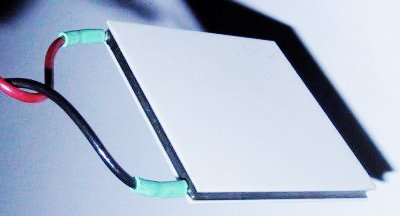

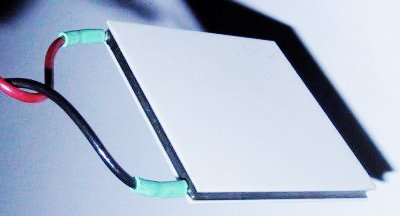

A quick look at typical peltier elements

Typical 40x40mm Peltier element

This is a "padded" TEC

Peltier elements come in various forms and shapes. Typically, they consist of a larger amount (e.g. 127)

of thermocouples arranged in rectangular form, and packaged between two thin ceramic plates. Multi-stage

modules, to reach higher delta T values, are also available, but less common.

The commercial TEC unit of interest for PC geeks is a single stage device, about 4 - 6 mm thick and somewhere from 15 to 40 mm

on a side.

The TEC will have two wires coming out of it, if a voltage is applied to those wires, then a temperature

difference across the two sides is achieved, if the polarity is reversed on the wires - then the temperature

difference is also reversed. The TEC is placed in between the CPU/GPU and the heatsink with appropriate thermal

interface materials (thermal grease). So one thing we might note is that if the voltage is applied in the wrong

direction then the TEC will cool your heatsink and heat your CPU!

Peltier elements come in padded and non-padded versions. On non-padded peltiers, the thermocouples

are visible from the side. On padded peltier elements, you can only see the padding material (often silicon) from

the side.

Problems related to peltier cooling

As mentioned above, high power usage and high power dissipation are the biggest problems related to peltier cooling.

In the days of first-generation Pentium CPUs, readymade peltier/heatsink combinations were widely available, which could

be installed and used just like a regular heatsink. For today's CPUs having a power dissipation of over 100W,

building a Peltier CPU cooler using just a peltier element and a heatsink is quite a challenge, and ready-made

peltier coolers are scarce and expensive. With such coolers, over 200W of heat may be dissipated

inside the case. For modern CPUs, it is better to combine peltier elements with watercooling. In any case,

the resulting cooling system will be expensive to run, due to its high power usage, and not very eco-friendly.

The large power dissipation will require powerful (and thus loud) fans.

Also, keep in mind that if the

cooling of the peltier element fails (e.g. fan failure or pump failure in case of watercooling), the results

will be more disasterous that if a conventional cooling system fails. Even if your CPU has a thermal protection

that will cause it to shut down if the temperature gets too high, the peltier element may still kill it by

continueing to heat it up long after it has shut itself down.

Another problem related to peltier cooling is condensation. Since it is possible to cool components below

ambient temperature using peltier elements, condensation may occur, which is something you'll definitely

want to avoid - water and electronics don't mix well. The exact temperature at which condensation

occurs depends on ambient temperature and on air humidity; we will look at this in more detail in part

3 of the Peltier Guide.

Advantage of peltier elements

After having focused on problems related to Peltier cooling, let's not forget about their biggest advantage:

They allow cooling below ambient temperature, but unlike other cooling systems that allow this (vapor phase refrigeration),

they are less expensive and more compact. Peltier elements are solid-state devices with no moving parts; they

are extremely reliable and do not require any maintainance.

Note: Parts of this article are based on writings by "Bo", a visitor of The Heatsink Guide,

who wishes to remain anonymous.

All pages copyright © 1997-2010 Tillmann Steinbrecher

Legal information / Disclaimer / Impressum