THE HEATSINK GUIDE: Information about fans

Introduction

The proper choice of fan is essential for achieving cooling performance, while keeping the noise of your computer low. This section

of The Heatsink Guide will help you understand which factors influence noise and performance, and how to chose a good fan

for your particular cooling problem.

Fan performance

Performance of fans is typically measured by air volume per time (usually in cubic feet per minute, CFM), or by air speed.

CFM values are more meaningful than air speed measurements, since they take into account the size of the fan. Obviously,

a 120x120mm fan will provide better cooling than a 50x50mm fan, even if both produce the same air speed.

Given CFM specifications are valid only when the pressure on both sides of the fan is equal; that is, when the fan

is operating in free space. Under real-life conditions, when the fan is installed in a device, the specified CFM rating

of the fan will not be reached; here, it depends on installation and on the overall design of the cooling system.

For

tips on how to install fans in an optimal way, see the case cooling section. You can find

tables for converting CFM from/to metric units on the conversion page.

Larger fans provide a better ratio between air throughput and noise. To achieve the best compromise between

cooling performance and noise, chose the largest fan possible.

The bearing type

The type of bearing used has a major influence both on noise and on reliability of the fan. We distinguish between

two types of bearing: Ball bearing and sleeve bearing. Generally speaking, ball bearing fans are more expensive,

last longer, but are louder than sleeve bearing fans.

The cheapest sleeve bearing type simply consists of a ring made of a porous material dipped in lubricant; the fan axis

rotates inside this ring. After prolonged operation, the lubricant will be used up, and the fan will become noisy and eventually fail.

This is a common problem especially with small, inexpensive fans like they are used on chipset coolers or coolers of

low-end graphics cards.

It may help - as a temporary solution - to lubricate the fan that has become noisy, using standard lube.

However, depending on the fan design, the bearing may not be accessible to lubrication from the outside. Sometimes, removing the

manufacturer's sticker from the fan will expose the bearing.

The better solution is to replace cheap fans that have become noisy

by decent models with a ball bearing; a good ball bearing fan will last for many years of nonstop operation, without any lubrication.

There are also good quality sleeve bearings available, such as the "Sintec" sleeve bearings used by Papst, which use PTFE (also known as Teflon)

as bearing material. These are just as expensive as good ball bearings, while maintaining the sleeve bearing's advantage of having lower noise

level. Other manufacturers use ceramic materials for their bearings.

One bearing is not enough to stabilize a rotating axis. Fans have two bearings, and many of the "ball bearing" fans actually

have one ball bearing, and one sleeve bearing. Larger ball bearing fans should have two ball bearings; they are often sold as

"two ball bearing" or just "Two Ball" fans.

Balancing

When you install new tires on your car, they must be balanced after installation. In this process, little weights are attached

to your car's rims, to compensate for heavy spots, and thus avoid imbalance. This keeps your car rolling smoothly, and reduces

stress on the car's bearings and suspension.

The same can be done with fans; due to tolerances in the production of the fan motor, little weights can be added to

balance the fan, which will make it more quiet and last longer. This fact is rather unknown, and few fan manufacturers do it -

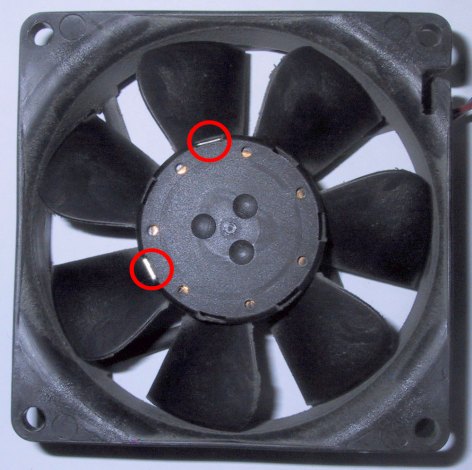

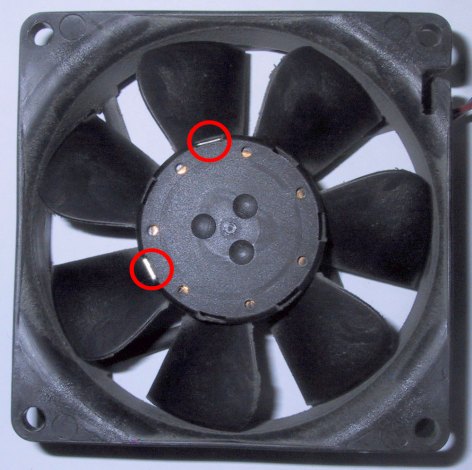

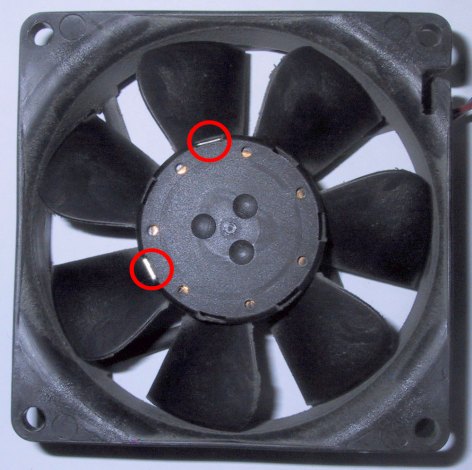

since each fan unit produced must be balanced individually, it is an expensive process. Below, you can see a picture of

an 80x80mm Papst fan. Notice the little slots around the fan motor case, and that two of the slots are filled with little

metal weights to balance the fan.

One might argue that other fan manufacturers do not need to do this, because the tolerances of their fan rotors are low enough, and

balancing is not required. This may be a valid point; however, considering the Papst's excellent reputation as far as low noise and long-term reliability

is concerned, it seems that the balancing does make sense.

Other factors that affect fan noise and fan performance

Besides motor/bearing noise, fans also produce noise created by the air flow itself. This noise can to a certain extent be optimized

by smart rotor design, but all in all, one problem remains: The faster a fan's air flow is, the more noise it creates. How much noise

this air flow causes, also depends on installation:

-

If the air flow of the fan is obstructed, it gets noisier. Use fan grilles only when necessary (that is, when fans are accessible

from the outside, which is typically not the case for CPU fans).

- Fan "grilles" that are simply stamped out of the case are often (not always) too thick. You can see one example of such

a poorly designed grille below. Fan grilles made of chromed wire have better aerodynamics

and will result in better performance and lower noise.

- The "cool" laser-cut fan grilles with various motives may look good, but often have poor aerodynamics, and often also

provide only little protection.

- Putting spacers between case/fan grille may help to reduce air turbulence. As mentioned in the case cooling section,

rubber spacers are available for mounting fans. They will decouple the fan from the case, and avoid the effect where the case serves

as a resonance body for the fan.

- Fans with a smaller motor leave more space for rotors, and provide a more even air flow

Poorly designed fan grille

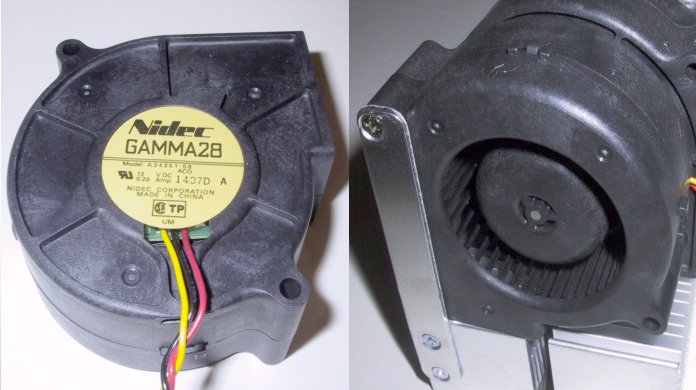

Fans and blowers

"Regular" fans are, more precisely, axial fans (the air flow is in the same direction as the motor's axis), as opposed to

radial fans. Radial fans are commonly referred to as blowers or centrifugal fans. They feature a large diameter

air intake on one (large) side, and an smaller air exhaust on the flat side. This results

in a fast, dense airflow over a small area. This property makes blowers suitable for very targeted air cooling, especially under

restricted space conditions. Blowers are used, for example, for cooling high-end graphics cards. They are also excellent for

CPU cooling, provided that the heatsink they are used with is designed to take advantage of the blower's air flow characteristics.

For notebook PC CPU coolers, blowers are most commonly used.

For case cooling, a regular axial fan will usually provide a better ratio between air flow and noise than a cooler. However, in

conditions where space is restricted - for example in 1U rackmount servers - blowers are also commonly used for case or power supply ventilation.

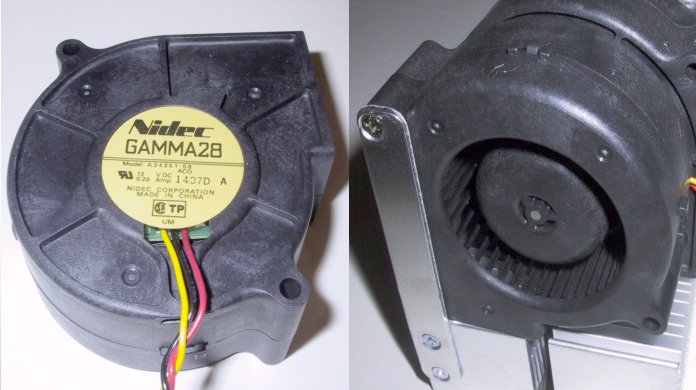

Below, two pictures of a Nidec blower, as it was used for the "Silverado" heatsink, which was a popular low-noise CPU cooler back in 2001.

Fan temperature controls

Adding a temperature control to a fan would only add a few cents to the manufacturing cost of the fan. But most fans still come without temperature control.

A temperature control integrated into the fan isn't always the best solution, for the following reasons:

- On inexpensive temperature-controlled fans, the temperature sensor is integrated in the fan case, so that it measures

air temperature - not the temperature of the device to be cooled. Better and more expensive temperature-controlled

fans have the sensor on a separate wire, so that it can be placed directly on the device to be cooled.

- In many cases, the temperature range at which the fan will increase its speed is not known, or not precisely specified. Even if

it is, it cannot be adjusted by user. Very few fan manufacturers offer a choice of temperature different ranges.

If you are familiar with soldering, the better solution is to build yourself a temperature control, where

you can adjust the temperature at which the fan speed increases yourself.

Popular fan manufacturers

I can certainly not offer a complete list of fan manufacturers, so what you see below is just a list

of the most well-known fan manufacturers. For more links, see the "Links" section of this site.

- Papst - expensive,

high quality. Especially the low-rpm sleeve bearing models are very quiet. Production facilities in Germany

and Hungary.

- Sanyo Denki - expensive, high quality, Japan-based company.

- Verax - smaller fan manufacturer, expensive, high quality; ultra low

noise fans with unusual rotor design available.

- NMB - less expensive, reliable, was founded - according to unconfirmed rumors -

by ex-employees of Papst. Wide range of blowers available.

- Nidec - less expensive, reliable; Japan-based company.

- YS Tech - fans inexpensive, but reliable; Taiwan-based company, very interesting models

with motor integrated into fan case available.

- Delta Electronics - fans inexpensive, but reliable; Taiwan-based with

production facilities in China. High-rpm models available.

- There are countless other fan manufacturers, most of them from Asia. Quality can vary a lot, prices also vary and are

sometimes amazingly low. You get what you pay for.

- Often, heatsink or case manufacturers simply put their brand sticker on fans produced by other companies. If you buy a fan

under a certain brand name, this may not necessarily mean that the fan was actually manufactured by this company.

Rants about transparent fans with embedded LED lights

Recently, various transparent fan models with embedded LED lights in various colors have appeared on the market. Prices of

these fans have dropped, and by now, they hardly cost more than a fan with a sober black case. Especially on eBay, such

fans can be found at extremely low prices.

How is that possible? Simple: What manufacturers spend on the additional LEDs, they save on the bearing.

The most reputable fan manufacturers concentrate on improving quality, performance and noise of their fans; they usually do

not manufacture transparent fans with flashy lights.

Personally, I have not yet seen a really high quality transparent LED fan. This is not a general rule,

it is just my personal experience. My advice is to stay away from bargain-priced colored fans, and invest in quality, instead of stuff that supposedly looks cool.

All pages copyright © 1997-2010 Tillmann Steinbrecher

Legal information / Disclaimer / Impressum